The highlight of the tissue grinder is to maximize the convenience and safety of operation. Due to the integrated motor switch, the instrument can only be started when the cover is closed. The unique system can easily and safely fasten the 2-50ml grinding tank. In order to meet the requirements of food and pharmaceutical industries, the system and swing arm are made of high-precision stainless steel, and the shell is also made of stainless steel. The application of the new motor and the direct drive of the motor make the maintenance very convenient.

Grinding principle of tissue grinder:

Put the sample grinding ball into the grinding tank. Under the action of high-frequency swing, the grinding ball impacts and rubs back and forth at high speed in the grinding tank, so as to easily realize the grinding, crushing, mixing and cell wall breaking of the sample in a few seconds to minutes.

By pre freezing samples (grinding tank and adapter can be frozen together), samples with heat sensitivity, viscosity and elasticity can be ground easily. The grinding tank adopts a screw cap sealing design to effectively prevent the condensation of water in the air on the frozen sample, prevent water vapor from entering the sample and ensure the accuracy of subsequent analysis results.

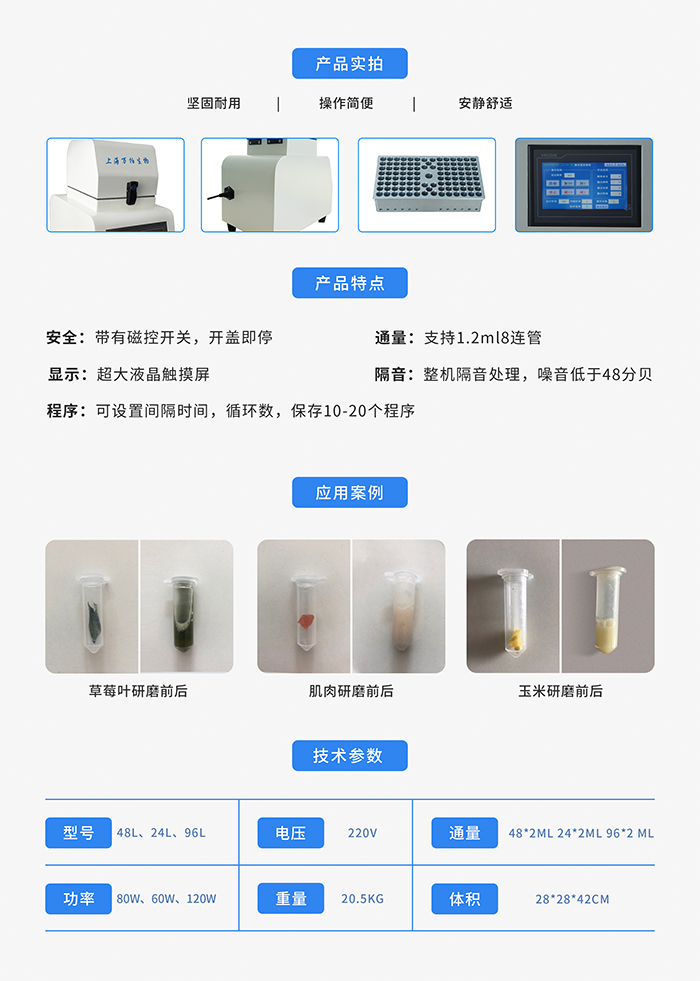

It can be equipped with porous adapter, which can process 1-96 animal and plant tissue samples at a time. The use of the adapter not only provides high repeatability and high-quality results for multiple sample preparation, but also saves time and improves efficiency. It provides a reliable analysis basis for the next experiment.